Inkjet

Coding and Marking

Laser Marking - Laser Engraving

Laser Marking and Laser Engraving explained

What is Laser Marking: The Laser Marking process creates a thermochemical reaction from the low heat applied to the surface of a part, creating an oxide layer and the result is a Dark Mark or Heat Mark. The Laser Marking is annealing with no material being removed, the marking is permanent with no depth of feel.

What is Laser Engraving: As with Laser Marking heat is applied to the surface resulting in a permanent mark. The difference is that material is removed when it is engraved resulting in depth and edges you can touch and feel. When just the coating of the surface is removed it is Laser Etching, if deeper than the the surface it is Laser Engraving.

Handheld Laser Engraver

MarkTech 30i Handheld Laser Engraver

The MarkTech 30i is a Handheld Laser Engraver designed with portable laser engraving in mind. Outfitted with a powerful 30W Fiber Laser and large marking area of 100mm x 100mm. This Portable Laser Engraver has Laser Marking Software via a built-in Touchscreen Controller. Weighing in at approx 27lbs., the Marking and Engraving can now be performed at the point of activity in any manufacturing or inventory receiving workflow. This Metal Laser Engraver can be configured to "Laser Print" Date/Times and Part Numbers or Serial Numbers, as well as QR Codes, 1D Barcodes and the Datamatrix Code. Industrial Laser Marking your Logos and Symbols as Raster or the crisper Vector formats. Just plug into electrical power, configure and save your Laser Engraving or Marking job and your ready.

CLICK: MarkTech Handheld Laser Engraver Datasheet

The Handheld Laser Engraver fulfills the solution for many industries that require portability when performing a task such as a Metal Laser Engraver process when Laser Marking or Laser Engraving directly on larger parts and products beyond the production line or assembly line.

NEED MORE INFO?

Request a Quote or discuss your Laser Marking Laser Engraver project.

Laser Marking Machine

The benefits of a Laser Marking Machine to manufacturers is essential. The Laser Marking Machine processes range from basic Part Identification, Logo branding and Compliance Symbols. Also Laser Part Marking provides durable and readble Markings for complete track and trace of products and parts for the lifespan.

BenchMarker 30i Laser Marker Machine

The BenchMarker 30i is a Laser Marking Machine designed for stationary Laser marking. Outfitted with a powerful 30W Fiber Laser and large marking area of 100mm x 100mm. This Portable Laser Engraver has Laser Marking Software built-in to the Touchscreen Controller and Laser Source in a cabinet. Perfect for a workpod area in manufacturing and assembly shop floor. This Metal Laser Engraver can be configured to "Laser Print/Engrave" Date/Times and Part Numbers or Serial Numbers, as well as QR Codes, 1D Barcodes and the Datamatrix Code. Industrial Laser Marking your Logos and Symbols as Raster or the crisper Vector formats. Just place the BenchMarker Laser Marking System onto a worktop, plug into electrical power, configure and save your Laser Engraving or Marking jobs and your ready for Laser Engraving and Laser Marking.

We cannot stress the importance of wearing Laser Safety Glasses when performing Laser Engraving and Laser Marking.

Avoid eye or skin exposure to direct or scattered radiation. - Laser Protective Eyewear Required.

Metal Laser Engraver - Industrial Grade Precision

The Metal Laser Engraver can etch, mark and engrave virtually all metal materials like Stainless Steel, Aluminum, Brass, Copper, Titanium and other types of metals.

A Metal Laser Engraver is utilized in virtually any Manufacturing process, to meet DPM (Direct Part Marking) and DPMI (Direct Part Mark Identification) requirements in the Automotive, Aerospace, Medical and Electronics industries.

Deploy a Metal Laser Engraver to mark industrial parts and metal items with barcodes, serial numbers, logos, and 2D codes.

Laser Marking Equipment for Production Line

This Laser Marking Equipment is particularly useful for printing dates, expiry codes, and lot numbering of products traveling along a production line. Laser Marking Equipment for Production Line or Assembly Lines allows materials made of plastic and glass to be marked "on the move" or "on the fly".

AutoMark 30i Production Line Laser

The Laser can be deployed for Production Line Laser Marking and Laser Engraving where products and parts are moving past the Laser Marking Head. Many configurations are possible for the needs of different Manufacturing production lines. This kit includes the essentials; a Fiber Laser Marking Machine, Touchscreen Laser Controller, Floor Stand, Photoelectric Sensor for product detection and Shaft Encoder for capturing line speeds to ensure legible text and image markings. designed for stationary Laser marking. This Metal Laser Engraver can be configured to "Laser Print/Engrave" Date/Times and Part Numbers or Serial Numbers, as well as QR Codes, 1D Barcodes and the Datamatrix Code. Basic Configuration example - Just place the AutoMarker Laser Marking System next to a automated belt conveyor, and as each part passes the photoelectric sensor the Laser Marker processes the "print message" directly onto your parts.

Laser Marking Laser Engraving Barcodes Logos and Numbers

Laser Engraved QR Code Metal Tags Variable Data

Print QR Codes or the Industrial Datamarix 2D Code with the Laser Engraver Machine. Laser Engraved 1D Barcodes are also possible for Laser Engraving / Laser Marking on Steel and Aluminum.

Logo Laser Engraving

Easily import your Logo or Graphic of Diagrams for Logo Laser Engraving onto Metals and some Plastics such as ABS, PE (polyethylene), PS (polystyrene)

Laser Serial Number Engraver

The Laser Marking for Part Numbers and Serial Numbers are essential to manufacturing for proper Track and Trace of industrial parts and other manufactured goods and products.

Laser Engraving Fonts and Stencil Text

The Laser Marking and Laser Engraving Machines can produce excellent results for Text and Fonts, such as Stencil Text on Pipe and Metals. Easily Mark cut instructions onto metal parts that are to be assembled at a downstream supplier or process.

Metal Laser Engraver - Laser Engraving Metal

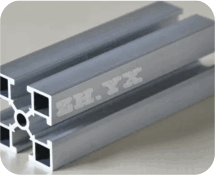

Laser Engraving Bare Aluminum

Settings for lighter marking intensity the bare aluminum will turn white. Increase the settings on the Laser Engraver Machine to provide a dark grey or charcoal color. Laser Engraving Bare Aluminum and Cast aluminums,these are typically annealed resulting in a white color, unless a specification calls for greater depth and contrast.

Laser Marking Stainless Steel

Steel is used in virtualy every industry. Laser Marking Stainless steel lends itself to every laser marking technique used today. Laser Annealing (or Carbon Migration) is to acheive a results of Dark Marks on the steel, per Laser Marking.

Laser Engraving Anodized Aluminum

Anodized Aluminum via Laser Engraving is one of the most commonly marked substrates and is used in many industries. Laser Ablation is the most common marking technique for anodized aluminum because it exposes the aluminum underneath resulting in a good looking white appearance.

Laser Engraving Stainless Steel

Laser engraving stainless steel removes an important protective layer. In fact, any method that digs or marks or gouges shallow or deep on the surface will remove this layer. The result is rust and this is why to create dark marks such as logos or data matrix codes on stainless steel, you need to rely on a Laser Annealing technology found with the Fiber Laser Marking Machines shown above.

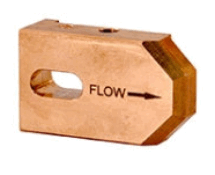

Laser Engraving Brass or Copper

The thermal properties are ideal for laser marking systems when marking copper or brass metals because the heat is quickly dissipated. Laser Engraving is the best process for Brass to provide readability of text or for machine readable Barcodes.

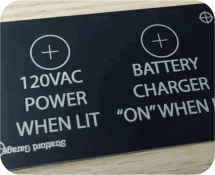

Laser Marking Engraving on Coated Metals

Our Fiber Laser Marking Machine come in 30-50 watts and can easily remove the powder coatings and Laser mark the underlying surface. The Fiber Laser Engraver can also ablate, etch and engrave painted metals.